Background

Powerco, established from an amalgamation of former power boards, is now New Zealand’s largest electricity distributor in terms of its network length (28,000km). It also has the second-largest number of electricity connections (336,000) serving communities in regional areas of New Zealand’s North Island across very diverse geographic areas.

The bulk of Powerco’s network was built during a period of intense development that occurred in the 1950s when many New Zealand rural communities were supplied with electricity for the first time. These networks are now at an age where their condition and performance is deteriorating and renewal is required.

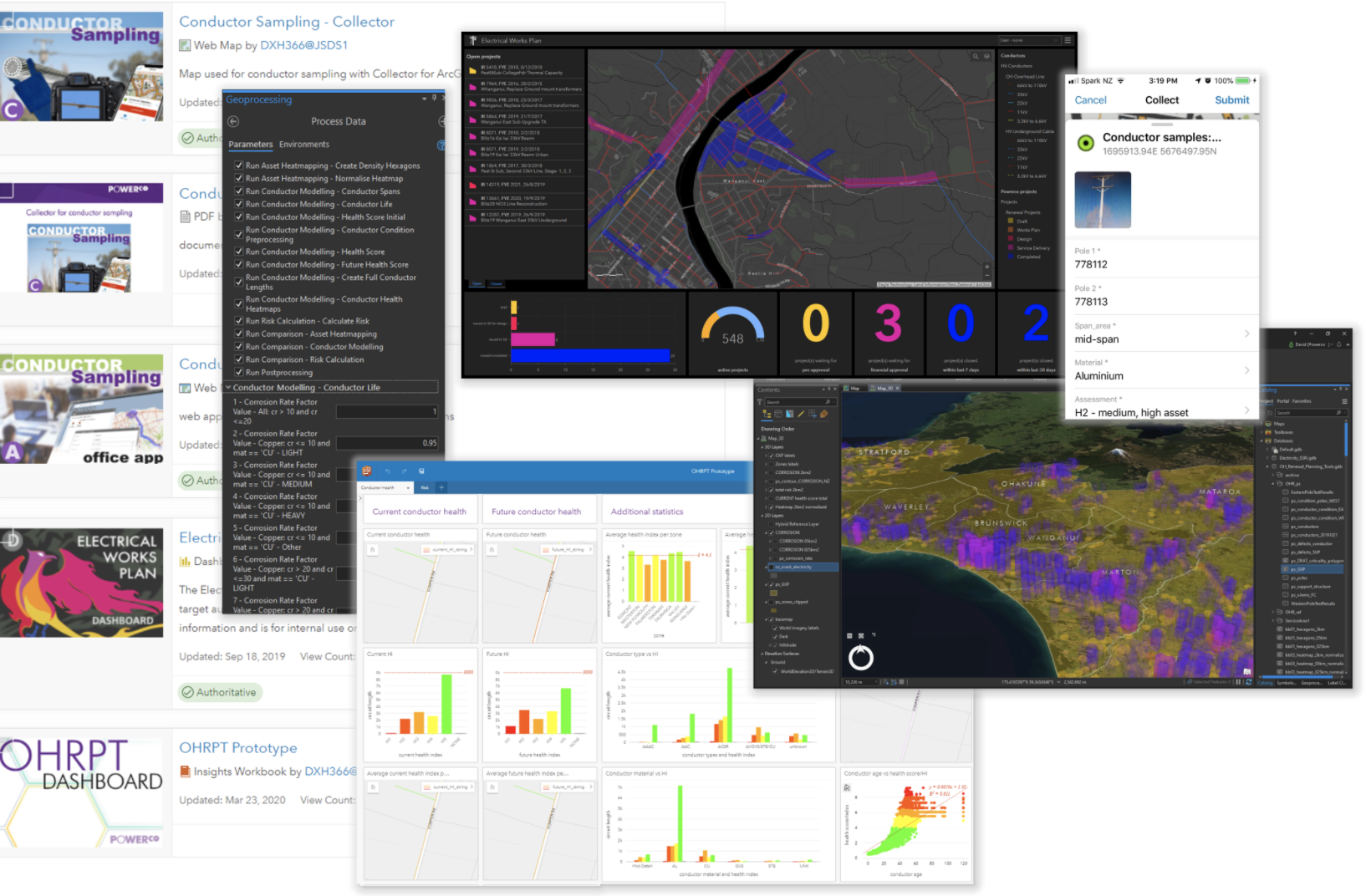

Tapping into the data collection, spatial analysis and smart mapping visuals offered by Esri ArcGIS tools has enabled Powerco to ensure that the right assets are repaired or replaced at the right time in the right locations. In 2018 Powerco began to carry out a substantial five-year renewal programme. The ways in which ArcGIS tools are being applied to this programme of work are constantly being expanded.

The challenge

“Powerco needed to build a unique smart tool that would enable us to visualise what was happening across the network,” says Powerco’s Asset Fleet Manager Overhead Ken Pattie. “We wanted to be able to visualise the various types of materials and loading conditions (mechanical and electrical) to find out to what degree Powerco’s assets were performing correctly.”

Identifying and prioritising overhead line assets for replacement is not a straightforward task. Renewal need is only loosely related to age. It is also very dependent on other factors such as material quality, environment, past maintenance practices, visual assessments of condition, and fault history.

- The large asset footprint combined with a range of information from diverse and sometimes sparsely populated sources made it difficult to assess where investment was most needed and how work should be packaged to create projects of efficient scale.

- These difficulties led to inefficiency in identifying and scoping projects.

The Solution

“By starting very simply and we were able to deliver results from early stages of the project,” says Powerco GIS Specialist David Haberkorn. “First, we produced targeted maps for our engineers who had previously been used to working with spreadsheets, which were no longer adequate for the complexity of the job. ArcGIS enabled us to move beyond these. Once we combined layers of information on maps in ArcGIS this provided the narrative the engineers needed to effectively plan their work.”

Phase one – Asset mapping tool solution

Powerco’s solution combines diverse sources of available data to produce visualisations that inform the company where network renewal is most needed. Their approach divided the network into hexagons on a map. Hexagon-shaped bins are assigned a score based on weighted combinations of input variables and colour coded to show different asset health scores. Calculations include:

- Past faults

- Observed condition scores

- Asset ages

- Known problem asset types.

The resulting health scores enable visualisation of the network condition as a heatmap. This provides a quick and compelling insight of renewal need. Varying-sized hexagon grids and bins enable the higher resolution required when moving from a macro network view to a localised project view.

“It was very experimental in the beginning,” says David. “Engineers liked the hexagonal bin approach and so we applied it to other data sets, such as defects and conditions. The hexagonal heat maps gave us a large-scale overview. They showed us the hot spots where there were assets with many defects. This guided our engineers to where there were potential project areas. They could identify these hot spots and zoom in for further investigation.”

Viewable layers included assets (wires, poles, transformers), as well as faults, conditions, health, environmental factors, elevation, etc.

Asset condition is not the sole criteria for renewal. Another layer of hexagon-shaped bins was produced, with bin scores characterising the potential impact of asset failure. Information from diverse sources was combined to visualise what had been previously unseen – the number of customers potentially affected by equipment failure.

Census-derived population density data was used as a proxy for likelihood of equipment failure causing injury. The condition and criticality layers were combined to produce a third layer that visualised asset risk. The resulting visualisations representing condition and criticality enable renewal planning engineers to see what others can't – risk.

Visualisation of risk allows renewal planners to see where investments will provide the greatest benefits in terms of public safety and improving reliability of supply. By visualising the abstract level of risk, engineers can balance trade-offs and target investments where they provide the greatest benefit through improved service levels for customers and improved safety for the community.

Phase two – extending the model to assess conductor condition

Overhead conductors (the wires in an overhead network) are traditionally one of the more difficult asset types to assess their condition and to plan for renewal. This is because reliable condition information is best obtained by the removal of samples for laboratory tests which is expensive and causes service interruptions. Powerco wanted to provide additional insight to the conductor renewal problem by developing a predictive model to estimate conductor health based on its knowledge of:

- Expected life of the conductor

- Corrosion environment modified by data available on historical failures

- Visual observations.

The resulting model provides visualisations of predicted current and future conductor health. These visuals are then used to identify target areas for more intensive testing. Each span of overhead conductor is assigned a calculated health score based on an industry standard modelling methodology known as the Ofgem Common Network Asset Indices Methodology (CNAIM).

Implementing the CNAIM algorithms within ArcGIS has enabled Powerco’s modelling to be entirely contained within the ArcGIS environment. Engineers leveraged the geospatial analysis features of ArcGIS to improve the way that the modelling was implemented. For example, modelling used data models of corrosion environment and wind speeds generated by the National Institute of Water and Atmospheric Research (NIWA) as an input to provide more accurate and location specific information to inform the model.

Using ArcGIS Powerco engineers were able to view the health scores by material, by type of conductor, or the location of the conductor within the network. They could also drill down further to visualise the exact locations of the assets with a low health score.

Using ArcGIS to plan asset management more effectively

Powerco’s renewal project made extensive use of the integrated ArcGIS platform applications and tools. All models were developed in ArcGIS Pro and scripted using Python software to add customisations and the development of features specific to the modelling required.

ArcGIS Insights provides different ways to slice and dice the data, enabling it to be viewed in various ways via interactive visualisation. It produces summary statistics and visualisations to assist in summarising, calibrating and navigating the models. These statistics are used for both fine-tuning the modelling and presenting high-level statistics on renewal needs.

General dissemination of results is achieved by Powerco’s engineers sharing projects in ArcGIS Operations Dashboard.

Collector for ArcGIS, a visual condition assessment application, provides a feedback loop that allows field observations to be cost-effectively incorporated into the modelling to provide verification and continual improvement. This tool is used to calibrate and continually improve the accuracy of Powerco’s asset modelling. This enables field-based visual observations of asset condition to be seamlessly integrated with the modelling.

Although field-based visual observations are not as accurate as laboratory assessments, the high volume, consistency, and low cost provided by the data collector is still useful for verifying and improving the model.

Powerco also used ArcGIS Survey 123 as a way of creating smart forms to analyse captured data quickly and securely for further analysis.

Viewing the output of the conductor model using an ArcGIS Insights dashboard assisted with calibration and tuning as well as providing summary information regarding the health of the assets overall.

Results and benefits

- Powerco engineers now have a more in-depth and accurate knowledge of what’s out in the field. They have interactive maps that show the predicted health score of different parts of the network enabling more effective planning and deployment of expenditure.

- The ability to virtually look down on the network and see previously disparate sources of data combined to produce views of asset condition and risk has transformed the way in which planning engineers identify and package network renewal projects.

- A task that previously took months and involved a large amount of subjective judgement can now be performed in days based on logical and consistent rules driven transparently from available data.

- Renewal work has quadrupled. The new efficiencies gained through ArcGIS have enabled Powerco’s renewal planning engineers to prepare a significantly larger portfolio of planned renewal projects with longer forward lead times that help to deliver procurement and delivery efficiencies. E.g. previously, Powerco could undertake 30 renewal projects annually in the overhead space (poles, conductors, crossarms), whereas now it carries out 120 such projects annually.

- The conductor modelling represents a step change in engineering insights available for this asset type.

- These new insights are informing changes in strategy which in time will improve safety and service level outcomes for consumers.

“The Overhead Renewal Planning Tool has allowed us to see what was previously hidden in a fog of data from multiple sources and to use this insight to make our network safer and more reliable.”

Dr Paul Blackmore, Powerco Asset Fleet Manager

The Powerco project team (alphabetical order)

Andrea Galliegue (Business Relationship Manager)

David Haberkorn (GIS Specialist)

Kenneth Pattie (Asset Fleet Manager Overhead Assets & Investment Delivery)

Dr Paul Blackmore (Asset Fleet Manager)

Waseem Awan (Asset Engineer Overhead Network)